Pompano Beach, Florida – Measure the frictional resistance between a rubber slider mounted on the end of a pendulum arm and the test surface.

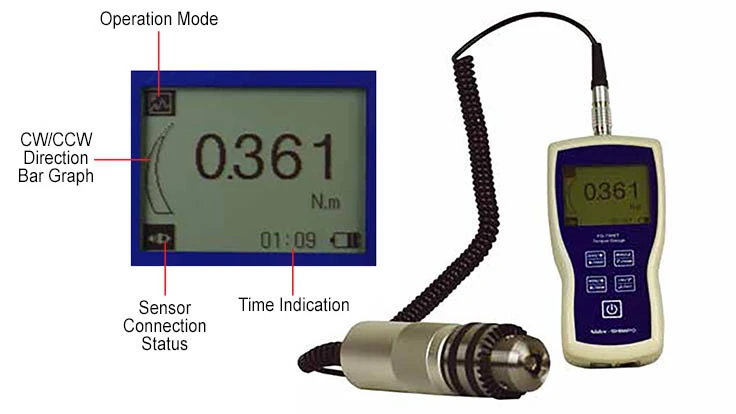

Torque sensors with standard chuck adapter are immediately recognized when connected to the display base and are available for testing needs in 1 N-m (9 in-lb) 5 N-m (44 in-lb), 10 N-m (88 in-lb) capacities. The multiple-language FG-7000T’s provides menu programming for easy selection and set-up of the instrument to desired requirements.

Features:

- Display operates in numerical or graph modes, both include a directional bar graph

- Graph mode combined with set point tolerances provide instant recognition of process relation to upper and lower limits

- Four modes of operation: Peak, First Peak, Preset, or Track mode

- Memory with group categorization to easily separate tests for review and later download

- Free software for viewing, graphing, and analyzing data on PC

- Large, backlit, auto-reversible display with various icons of test status aids user during testing

- Programmable High/Low tolerances combined with comparator NPN/PNP output allow usage in quality control production lines

The display has two selectable operations: numerical view with directional bar graph or graphical view with directional bar graph. In graphical view when alarm tolerances are set, the process is plotted in relation to the upper and lower limit graph lines.

Combined with the go/no go icons, a simple pass/fail determination is recognized. These high-tech instruments can data log a reading at the push of a button for simple data acquisition or be set to continuous data storage. Data can be viewed on the screen, sent to the optional printer, or loaded to be analyzed and graphed on the free software program. The 1,000 point memory with definable groups allows for multiple tests to be recorded and easily separated upon loading.

Source: Paul N. Gardner Co. Inc.